Before we go all conspiracy theory on this. Could we look to a simpler explanation that maybe the timings are changing because they are trying to tell people who ordered on the day the interview was given or the page was loaded when they might expect their glowforge if they preordered that day. I would expect anyone ordering today would have to get in line behind all the rest of you who ordered day 1 or 2 or 3 etc.

So it could be late, but on the bright side they will use wadded up hundreds as the packing material. Makes me glad the air filter has its own box.

sanity speaks

When I ordered mine, I expected a good 6-9 months before it was delivered, because making things like this takes time. Come on people, quit whining. Do you really want them to rush some half baked product out the door that doesn’t work? Personally, I want them to take a few extra months and get the design perfect before they ship it. A few days or weeks is a very small price to pay for not having it break down two months after you start using it.

Dan & Co: You are doing things right. Take the time to make a quality product and don’t pay attention to the moaning from the peanut gallery…

Yes of course it should be a finished design before shipping. The point was when I ordered I thought it was a nearly finished design, it would need to have been if pre-orders were going to be shipped in December. Now I know the real situation I know it was never going to ship in December 15 and would not be surprised if it was December 16.

I know what is involved getting products through worldwide EMC, safety approvals, ROHS, WEEE, etc, but not with anything as obviously dangerous as a 45W laser.

GF might be learning (along with us) just how big the gap is, between prototype and production.

Some of you might find the thread about Zano (elsewhere in this forum) interesting. Although there are a lot of really crucial differences between the Zano and Glowforge, one key principle still applies: making mistakes on a fixed budget can be fatal - gotta get it largely right on the first attempt. So I’m rooting for a cautious and deliberate approach, as the potential risk could be even worse than just a half-baked product.

It’s pretty hard to figure the term “Shipping December 2015” for early bird buyers as anything other than December 31, 2015. It also became clear to anyone reading this forum back around the end of the original pre-order period (Oct 2015?) that shipping was far more likely to be in the 1st half of 2016, and probably the end of that period. To my mind, that December 2015 ship date should never have been made and, better yet, revised to “beta units shipping by December 2015”. I have the feeling, though, that they actually did think they would have shipped the pre-order units by end of Q1.

I would just like to hear a update on how things are going from Dan. He has been pretty quiet lately.

Are there 50 beta units out in the wild now? Have they run into any issues yet that will cause a major setback?

I placed my order at the end of September. I assumed that the Glowforge would be ready to ship as a finished product in December, but knew that I probably wouldn’t get one that early since I hadn’t ordered right away. They would trickle out until full production kicked in. After joining the forum in early October, I understood a lot more of what stage of design the team was at. Didn’t think that the December was referring to beta units though but again started understanding the process of crowd funding, design and manufacturing a bit better. How do I say it? “The marketing videos misled me?” “I was misled by the videos?” I didn’t understand what I was getting into? I don’t care. In the end I kept reminding myself that I pulled the trigger precisely because whatever I’d get, I’d get it at 1/2 price and knew it would be worth it. I have yet to read anything yet that has tempted me even a little to ask for a refund.

Updates are for bigger news items and there probably just aren’t any right now. My guess would be that the next update would be related to the variable output power supply which seems to have experienced some roadblocks.

While the final design is probably basically complete from what it will looks like from the outside, But I’d guess the component containment/mounting aspects would still need the finalized for every operational component contained therein before its completion. That would need to be complete before the final prototype, which would in turn need some beta’g.

Then, you would need to have the mould dies created for the housings. At the same time, you would need to be negotiating the deal with the fabrication/production vendors (the mirror guy is different from the belt guy is different from the tube guy is different from the bi-polar stepper guy is different from the electronics guy is different from the injection moulding guy. . .). And then there’s the assembly facility guy. You need to negotiate the assembly process and then you have to negotiate your place is line with that assembly guy which would be a function of how busy that shop is which would be in part a function of how happy he is with the deal. Then the assembler has to tool up. And if only the supplier of the hinges for the top doesn’t meet the production timeline, the entire thing grinds to a halt. I’ve probably only been able to come up with a small fraction of the things to be completed in the process before the first person in our line has that big “dumb ass” grin on their face the day the courier arrives at the door with their GF.

So the next “update” I’d guess you might expect would relate to the variable output power supply. If that one hit an unsurpassable roadblock, well, then you’d see +/- 9,000 GF owners pipe in big time. ![]()

Well that’s about as ramblyish a post as this retired guy can muster without his morning coffee. ![]()

Have a great day all! Time to head downstairs to the shop.

Understanding if the betas even shipped would give everyone confidence in the timeframe (June 2016). If that hasn’t happened, then there is a high probability that the dates will not be met. You will know much sooner than June if you can make that deadline.

Updates are for big news? THAT would be big news. "We are on track!"

If however you are 2 months behind on your 3 month schedule for betas, then something might be happening, and a bit of transparency would be nice on that.

Manufacturing is a beast. It always has been, always will be. Manufacturing in foreign countries even more so.

While it would be nice to get updates on the spot, we should recognize that this wasn’t a KickStarter. It was a pre-purchase to hit minimum order. Which means they still have to go through all the same things, just without the risk or politics. It’s going to happen, just the “when” is fluid, like all first manufacturing runs.

If you’d like to see how the whole process goes, I would suggest checking out Tiko3D’s campaign updates: https://www.kickstarter.com/projects/tiko3d/tiko-the-unibody-3d-printer/posts/1435303 (They’re behind about 6 months already.)

Or any other campaign on KickStarter where manufacturing is involved.

You don’t get factory assembly line time unless all your parts are ready to go, and since there are so many parts to it, any little thing - like the plastic colour being off - can slow it down. That’s not even including the tooling for all of the moulds and making sure they’re not off by even a micrometer.

I’m a small business owner. I sold my personal laser for this guy. I have a backup. Yes, I would be upset if I had to go searching for another laser that’s twice the cost, but that’s the cost of a business risk. I believed and now, like everyone else, I wait.

Have to admit it would be nice if some of the positive progress was shared. Without discussing, or in any way sharing difficulties, the company could incrementally share small successes. For example we know that some time ago the new custom laser tubes came in and were performing very well. Dan off offhandedly mentioned this in a response to a different question. That’s great news that should have been shared in a broader way. I’m sure there are dozens of other small successes that would go a long way to give a sense of progress. And the company gets to cherry pick appropriate info. I’m probably one of the first to correct people when they go all paranoid in this forum. But have had a lot less to say lately simply because the info we have is getting quite old and things might have changed.

Silence makes me slightly nervous as well, after waiting, waiting, waiting… more than a year past the promised delivery window for an actual Kickstarter project to deliver, with $1250.00+ in limbo. My CNC mill finally arrived today: Creation Station Updates were incredibly far & few and usually whiny in nature. The complaints from people who got theirs earlier, began to pile up, and as time went on, it was clear things were getting worse. There was almost no interaction from the creator. I’m not looking forward to the build, after reading all the horror stories.

So why would I drop $4K on another crowdfunding project? Dan is one hell of a salesman with a great track record. His continual interaction on the forum keeps me confident that we will receive a quality product. Also, it’s a freakin’ laser, at a price I could just manage to scrape together.

I ordered on day 1; it was clear to me that it might not ship until Q2.

To be clear I’m not suggesting the company give us regular updates on how things are going with development. Pretty sure that’s not gonna happen. But little tidbits sharing just the positive progress would go a long ways to keeping the villagers out of the castle. I don’t care if it is something like “Hey, our data compression routines are working better than we had hoped”, or “the shipping box design is getting close”. Regular, vague progress statements are better than nothing.

OK - dashing to pick up my kids in a minute, but a few cool tidbits…

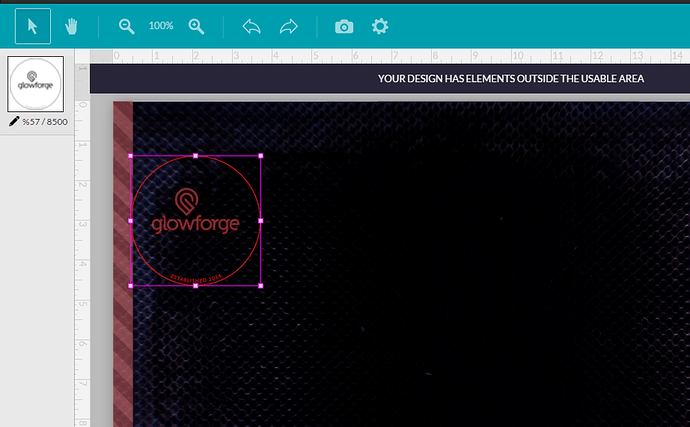

- Software is getting much awesomer. Off the top of my head, we now show you ‘dead zones’ so e.g. if you’re rastering at high speed, you leave enough room at the edges for the head to slow down without colliding. We show print status while you’re printing. You can cancel and restart jobs. Buckets of bugfixes.

- Cooling tests are still looking great.

- Transformers finally passed tests; now dialing in the driver circuit.

- New iterations of every board on the system.

- Yellower (less purple) lighting… brighter and more even, looks nicer, but I miss discolights.

- Lights right next to the lid camera improve calibration.

- Long term leak testing on the coolant reservoir looks great.

Offline now for a while but hope that helps.

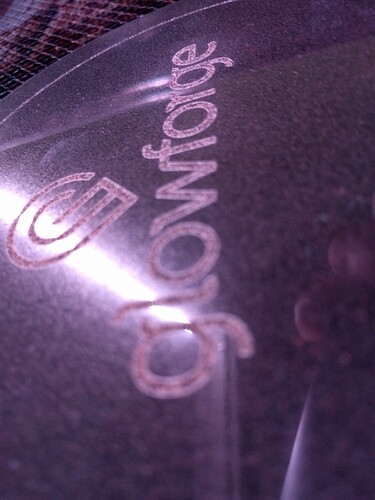

Oh - in case you’re curious, that engraving was a stone tile (purchased round, then engraved), pictured here.

Good job @dan!

Take that, nay-sayers!

Thanks heaps. That’s the type of thing that goes a long way.

Oh - and plenty of setbacks, but we’re still on schedule for our ship date. That could always change based on feedback or new problems, but so far, so good. I’ll have more and more detailed updates soon.