I am the keeper of the comb. You may look, but do not touch.

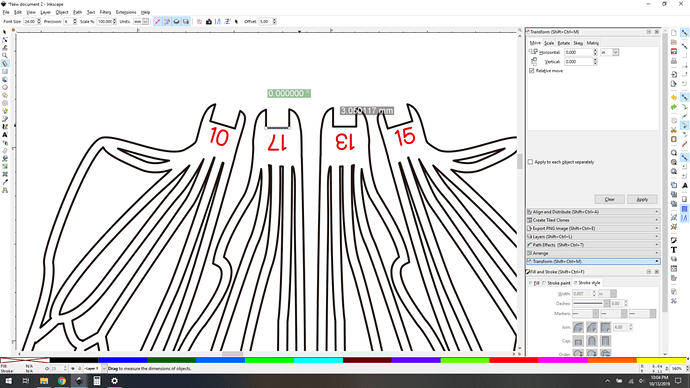

I’d seen the bee model kicking around on the forum for a while and always thought it looked fun, so I decided to take a crack at it. I had seen other people’s takes on it, but I decided that smaller was where I wanted to be.

Notes:

TwoThree layers of bubinga veneer, glued up cross-grain. Total thickness 0.063"- Unmasked. This is unusual for me, so thought I’d mention it.

- I made the slots intentionally looser than my usual, and glued the model up. The slots have barely enough friction to hold the pieces in place, glue is necessary.

- The entire model fits in 4" x 2.25" space, it uses very little material.

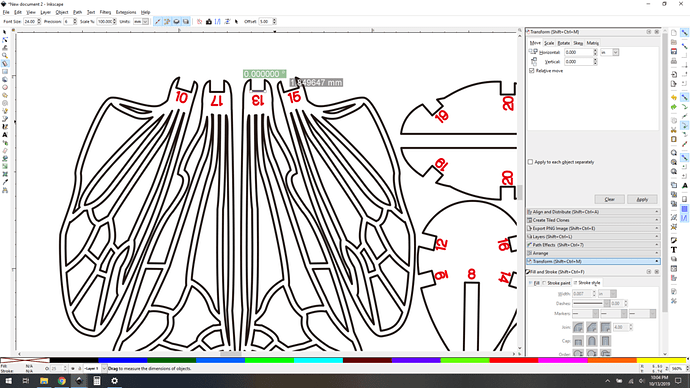

If this were my model I would redesign the head. I don't like the angle of the face planes.

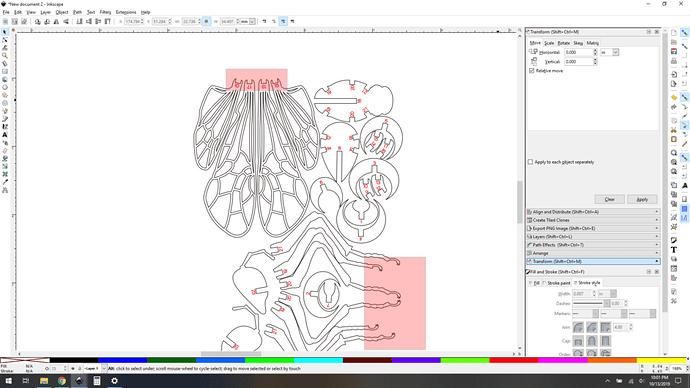

(Bubinga veneer)

I actually realized that the cutout in the long front wing section is still stuck in there. You can see it in the upper right wing here. I need to use a dental pick to get it out of there… The hazards of moving quickly and working at really small scale.

(Bubinga veneer)

A… uh… scale for scale. I was out of bananas.

(Bubinga veneer)

Should I be concerned?

(Bubinga veneer)

I should definitely be concerned.

(Bubinga veneer)

CONCERN INTENSIFIES