Somebody tagged me…

There are a couple years worth of discussion on the topic of origin setting. The Glowforge interface doesn’t rely on a fixed numeric origin. Instead, it relies on a relationship between the saved parts of a file to create alignment of the parts.

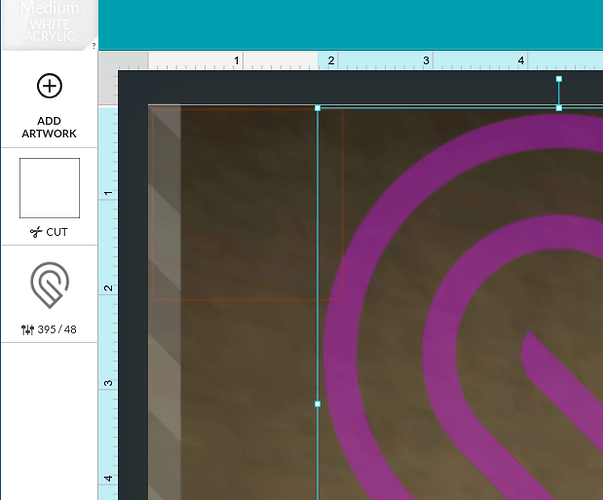

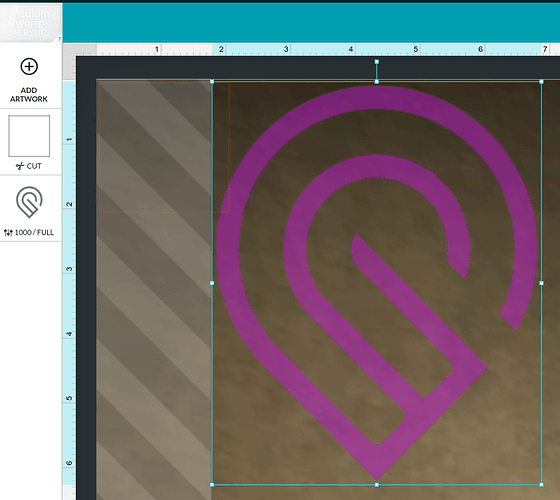

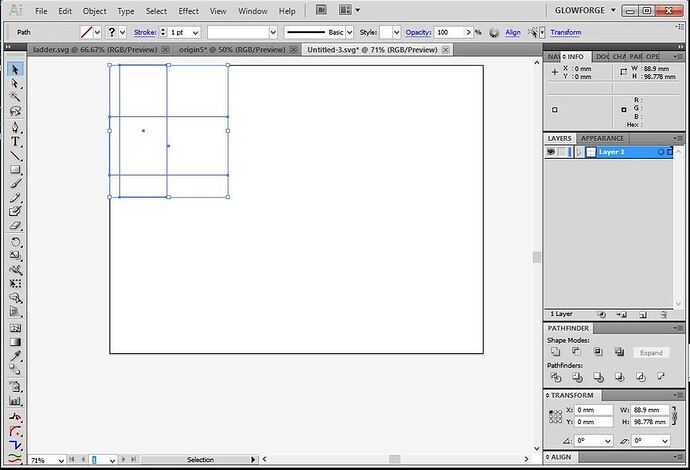

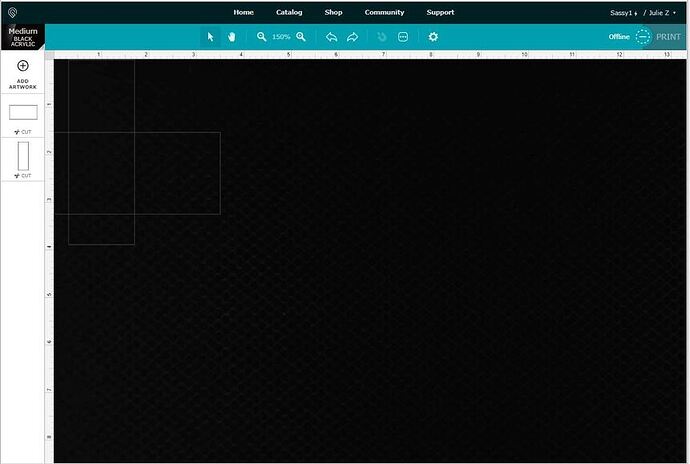

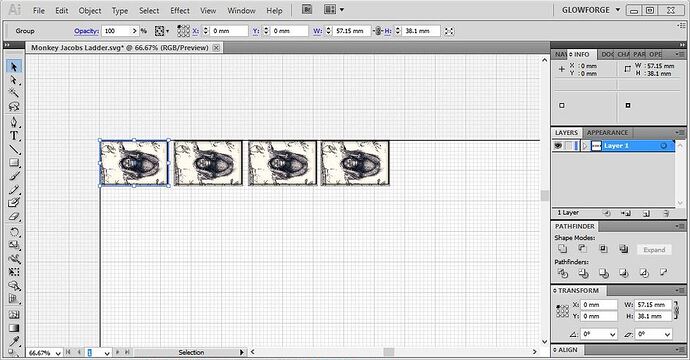

There is a work-around that you can use to open your cuts at the “origin”. Just set the artwork at the 0,0 point on your artboard in your design software.

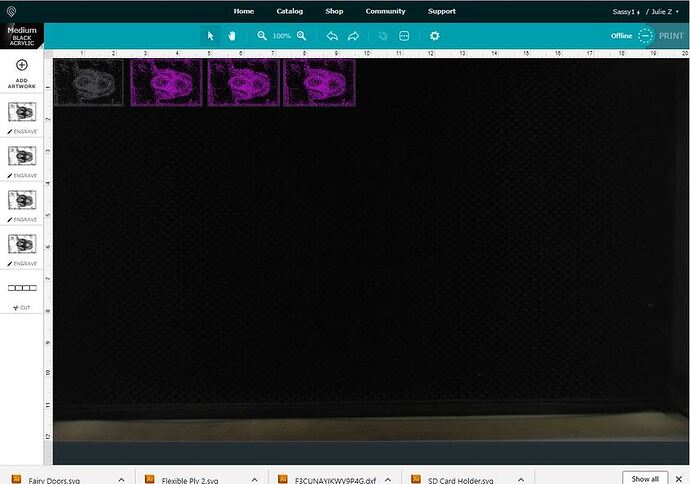

It will open at 0,0 in the glowforge interface.

That has absolutely no relationship to the point that it will be cut on the material though, because that can shift, but as long as that file is open, and if you can place the material in the exact same location that you placed it before, you can use it for numeric alignment.

(Generally doesn’t work out that way though, which is why cutting the jig at the same time as the engraving has worked better up to this point.)

That only works for cuts, not engraving, due to the varible no-cut zone on engraves. The engraves will snap to the 0,0 point, but you can’t engrave there.

You would have to determine the limit for the various speeds to determine where that point falls for each usage case. If you wanted to, you could then place the design at that point in your design software, and it will open in the same spot each time.

BUT…

Now, with the introduction of Snapmarks, they are using a form of fiducial mark recognition to align objects, and jigs are re-usable. So you can place them anywhere on chopped up sheets and the interface can search and find them, align the artwork, and get on down the road.

)

) )

) )

) )

) )

)