Alignment is a huge issue. It is a major selling point of the machine and it doesn’t work yet, even when it is in production. The 1/4" tolerance stated is awful and it seems some machines are even worse than that. I won’t answer “yes please” to my email if this isn’t sorted by the time I get it. GF are not going to be sending four machines back across the pond so it has to be fixable remotely or they have to be delivered working.

OK, now that that little kerfuffle has blown over, let’s get back to business. The one example above shows pretty good alignment–worst case is less than 1/8". I’d be happy if that were my machine!

Are there better examples out there?

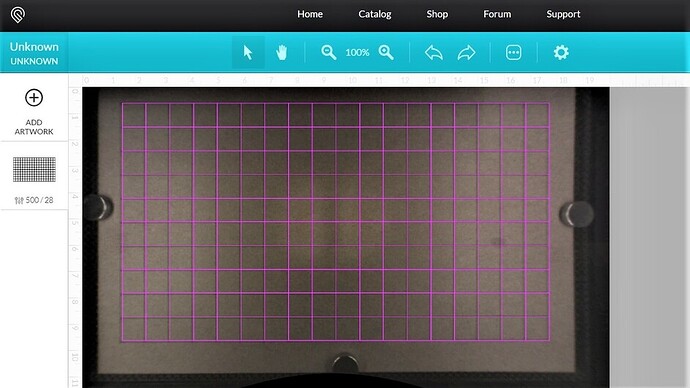

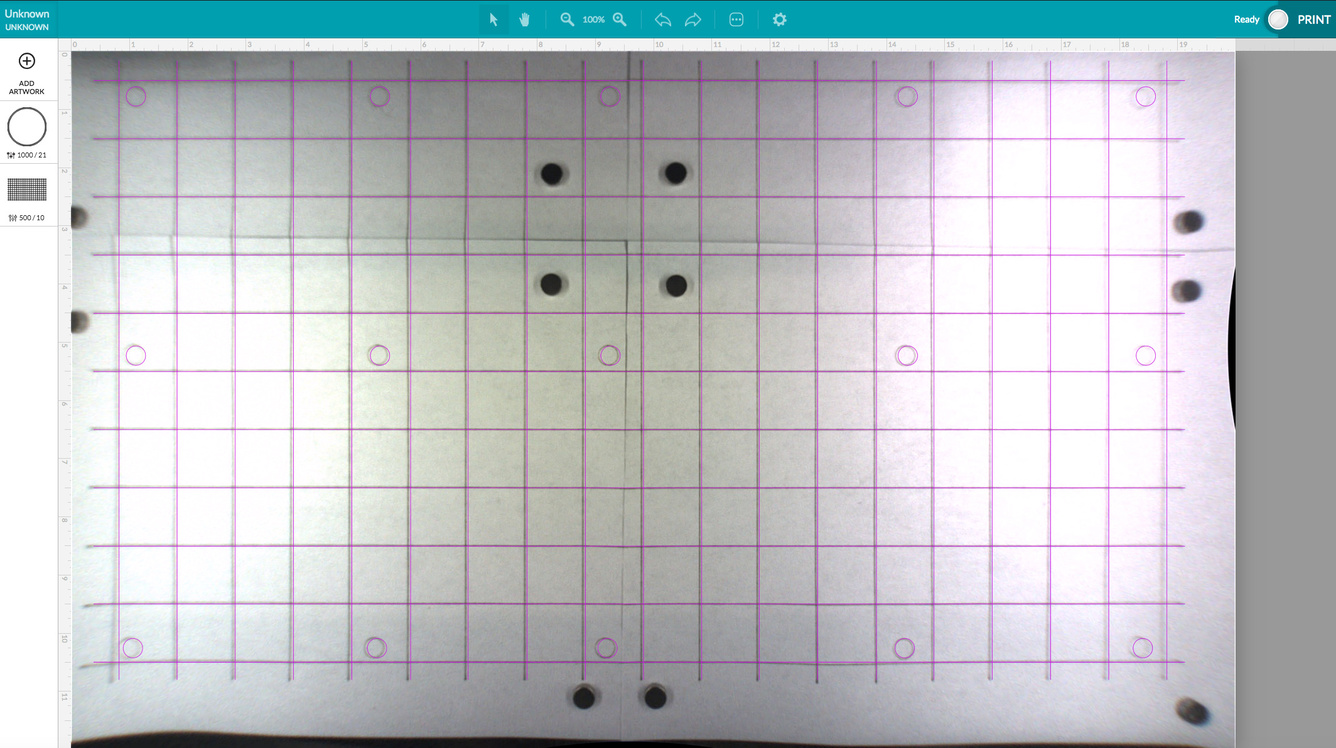

Ok here is mine, I printed 1 inch squares that are divided into 1/4" squares on a sheet of paper and then places that paper in different spots on the bed. Then I imported the same drawing into the ui and dragged it on top of the printed squares.

The middle 80% is great then it rapidly gets further out, but still within the 1/4" they say they can achieve.

I am very ok with this, also not that the paper is .008" and the ui puts it at .01"

I’m not a fan of either the spreadsheet or comparing alignments. The reason being is even though these alignment pictures might give folks a better feeling about the units it still will foster ill will for those that have decent alignment but maybe not as good as the best shown. So I’m torn.

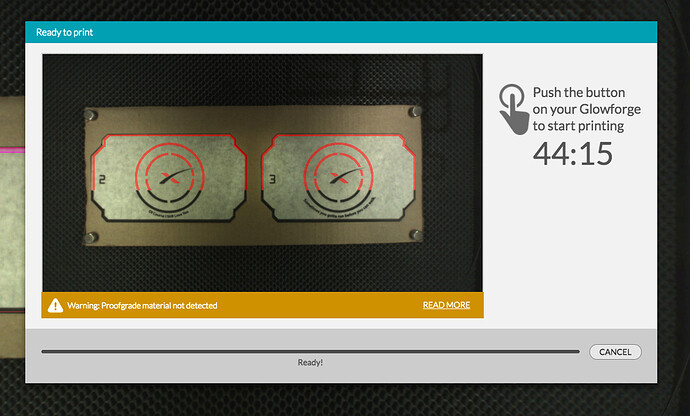

I’ll show my alignment only because the problem units are always the most remembered.

It is perfectly centered in the middle, and only about 1/16" off in the X direction and far better in the Y direction at the edges of this test. The magnets are 1" in diameter.

Also might add that other than the transient S/W or network issues this unit has operated flawlessly for 5 months. (Oops! 6 months)

Wow! That’s great performance!

Before seeing your results, I would have never imagined the lid camera alone could do so well. I stand corrected in some of my past prognostications.

Yes it is good enough for placement on sheet materials with minimal wastage. Not good enough to say cut around some artwork unless it was in the middle.

Whether is it good or bad relative to what we can expect from the lid camera depends on what GF are doing with the image. If they do a per machine calibration with a grid I don’t see why it can’t be pixel accurate. If they just do a standard lens de-warp for all machines, with perhaps a factory centre adjustment, then it is better than I would expect.

Do they all start out this good when dispatched but drift in transit?

The main problem is we are just told it will be improved in the future but we have no idea by when and by how much.

And now I remember why I didn’t want to post.

Funny how that works.

/uploads/db6859/optimized/2X/3/3e231a456775458c2d3d62160811a6c1d5469798_1_281x500.JPG

Well that’s a lovely story. Not sure what it has to do with the subject at hand.

OK, so what is your max misalignment? Or are you just showing us that there are some instances where you can get things to align?

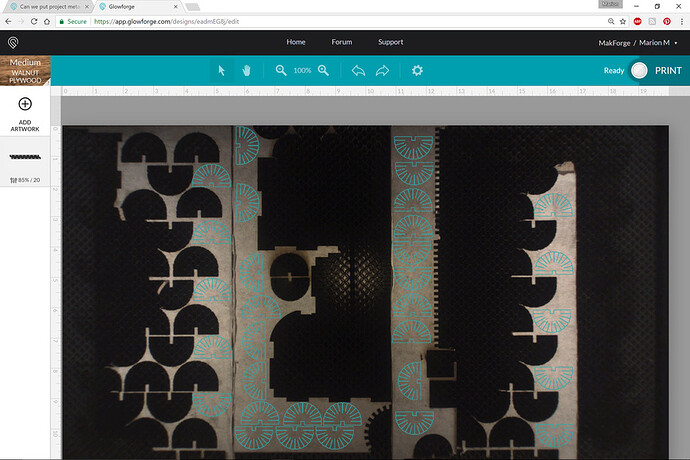

The droneship coasters came out wonderfully!

Your bed pic is spot on! You ought to see the warp/distortion I get in the corners of mine. But you won’t because I’m not posting (it’s a PRU) and it’s not impacting my ability to churn out stuff I’m happy with.

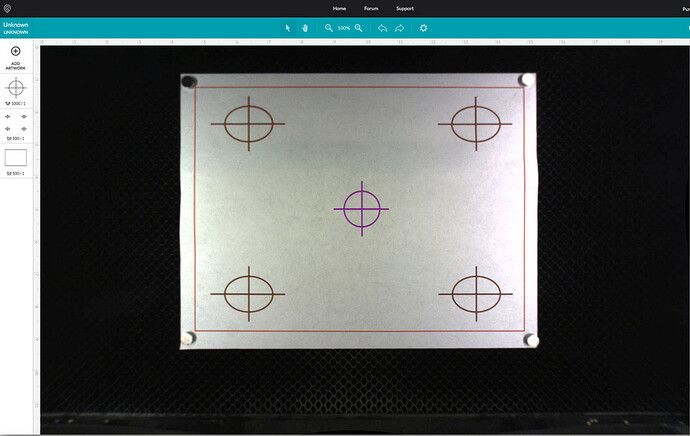

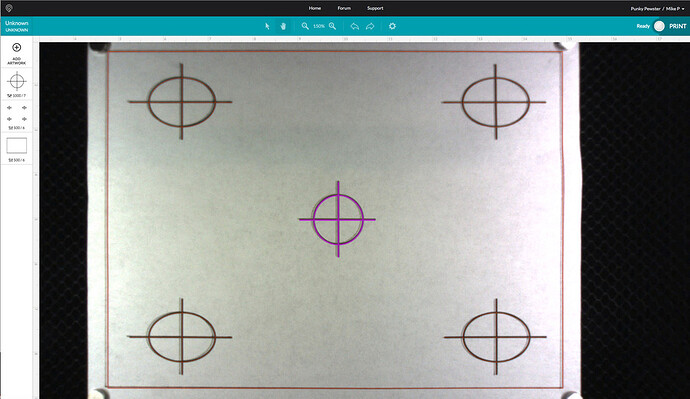

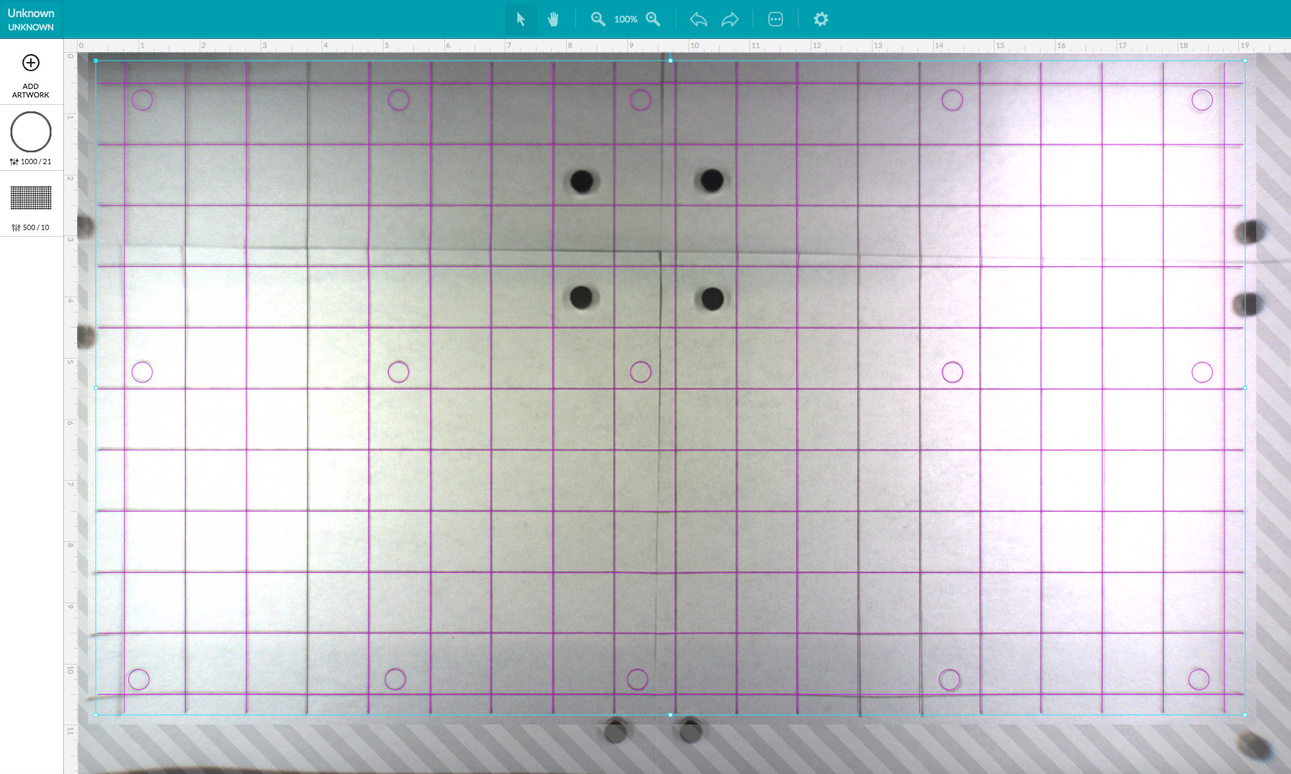

Lid camera/image de-warp accuracy compared against SVG file and non-laser printed test reference:

Laser tested against lid camera/image de-warp:

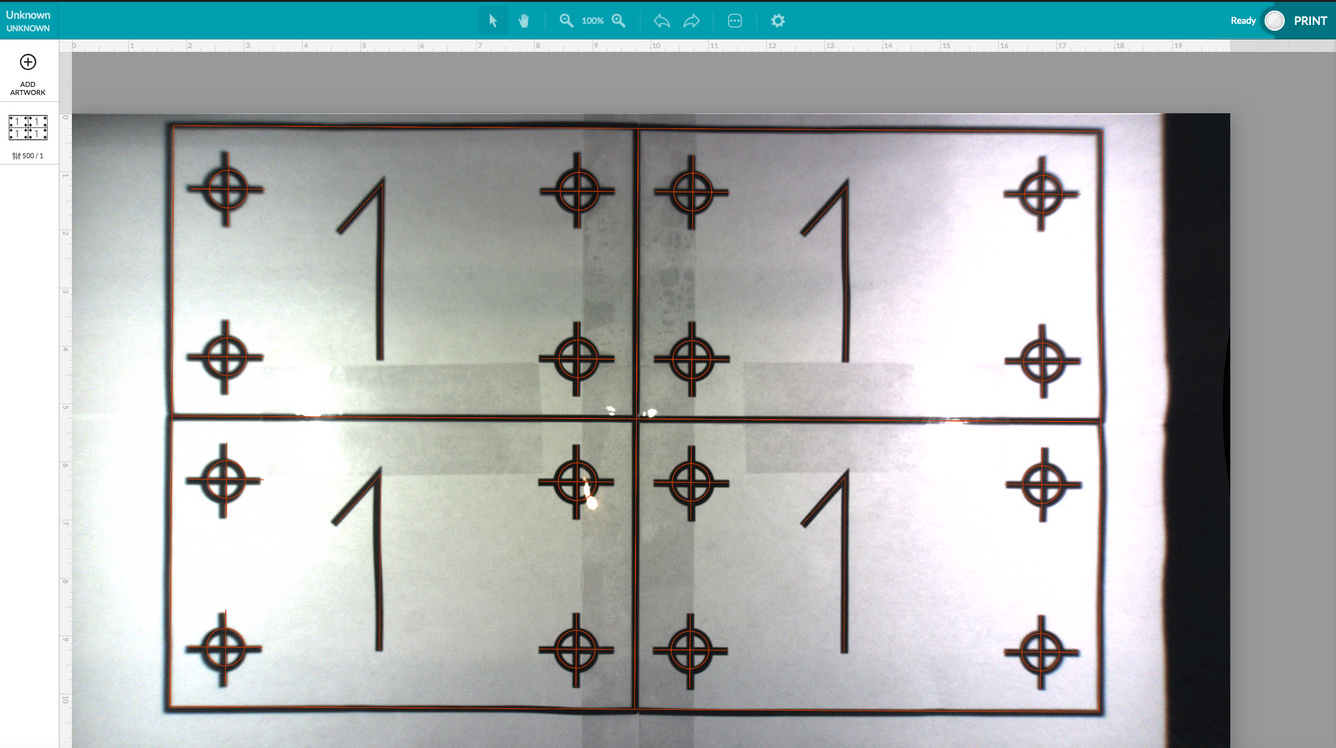

Lid camera/de-warp accuracy compared against SVG file and non-laser test reference, this time filling entire bed. Note this is four pieces of paper printed then taped together using the wider lines and a lighted table for registration.

Test grid on full extents of the bed fresh after running the test. Lines are scores (vector movement) and circles are engraves (raster scan movement):

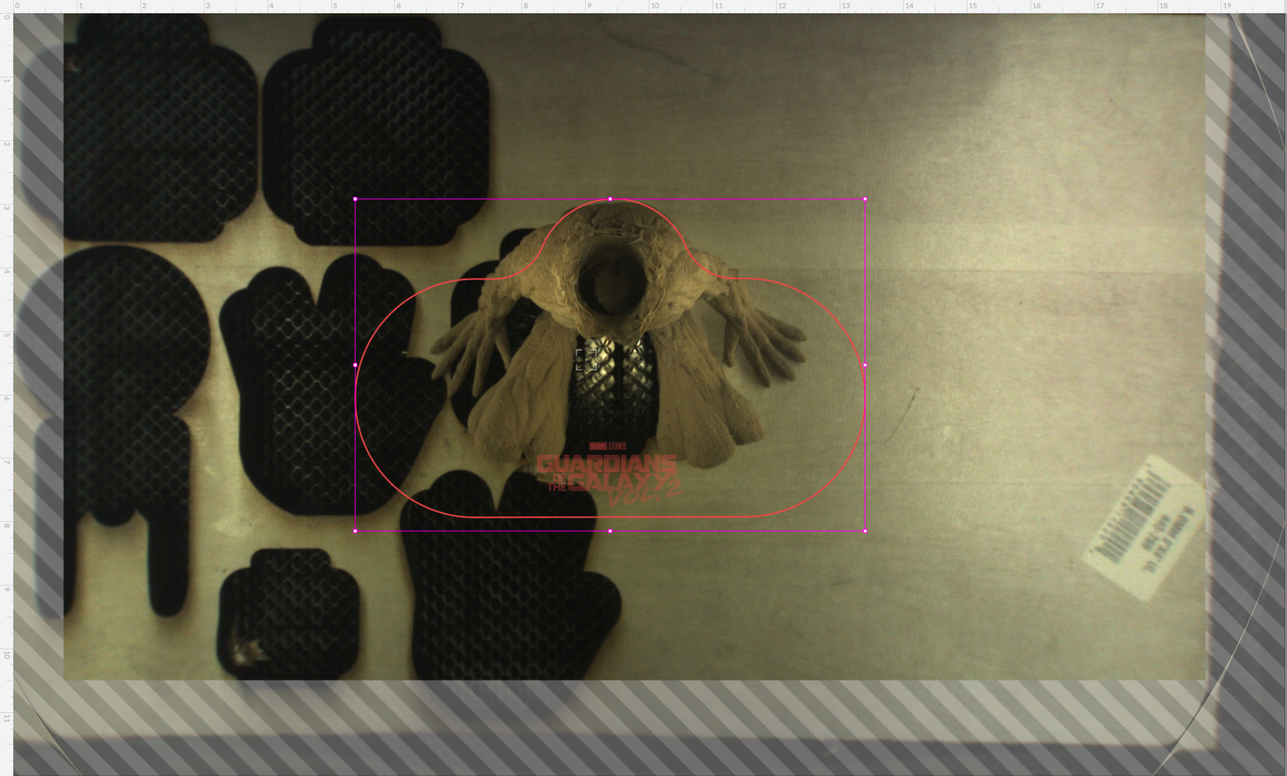

After shifting the artwork to the left by two clicks, over the scored test:

I’m sorry I don’t have an after picture of this, but believe me when I say that each of these little clips cut out just fine as they were with no bad edges from misplacement.

I don’t have any screenshots to share, but this weekend I had some VERY good alignment projects.

I’m working on creating my own Catan Board (heavily inspired by the GF Free PDF after hours trying to create my own designs). I bought a number of premade boards from Amazon that were 3 inches wide. If you measure a catan tile, it is actually a little bit over 3 inches from one flat face to another, so I’m scaling mine down to be exactly 3 inches to fit these boards.

I covered each piece with masking tape and then ran a VERY light score just to make sure that I was going to be able to fit the pieces onto the wood. Every single time I was spot on to where the preview said I was going to be. I even had one incident where I had to move the piece and rescore, and I laid the new score DIRECTLY on top of the old one (laser beam width accuracy? Yes Please!)

This topic was automatically closed 12 days after the last reply. New replies are no longer allowed.