Le Chat Noir I traced from an image and tweaked by hand the vectors. It’s a hugely complicated 3color original so requires some interesting work to recreate the feel of the original with just the white. No pupils on this image gives it an eyeglasses look.

The White tree is wiki commons. I’m still trying to remember the location. Grabbed it way back when I was first doing my matchbox design and needed to do some work with it to come out in an engraved outline. Wouldn’t sell or distribute something like this.

Octopus openclipart

Before I got a Glowforge, I ordered a bunch of LEDs in strips and studied what it took to roll your own edge lit acrylic signs. Making some small USB powered name plates or a large Durin’s Door was a great way to use different materials and combine into one object.

I ordered a hundred USB cables from Amazon for BAMF to make some edge lit acrylic name plates as give aways but the cables didn’t make it before I left. And with the spotty connection during the day, I doubt if I would have been able to make too many LED signs.

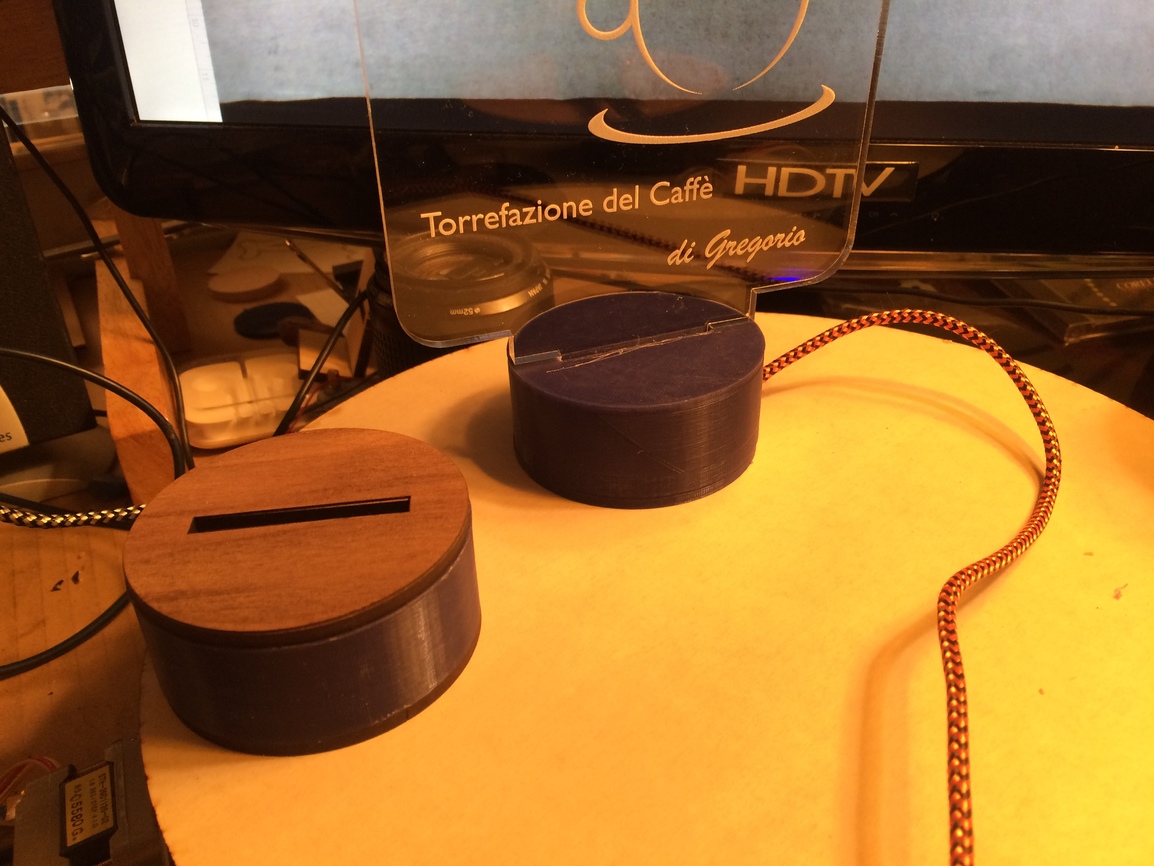

Since I have the hardware to make these signs now, and a 3D printer, I figured I could make my own bases rather than order them. Yes, it’s nice to have on/off switches or battery powered ones, but since folks have tons of 5v wall warts or USB slots available, just going straight USB makes sense.

I had done bases out of wood before, but never took the time to make the design a bit more professional looking. Didn’t want to do finger joints.

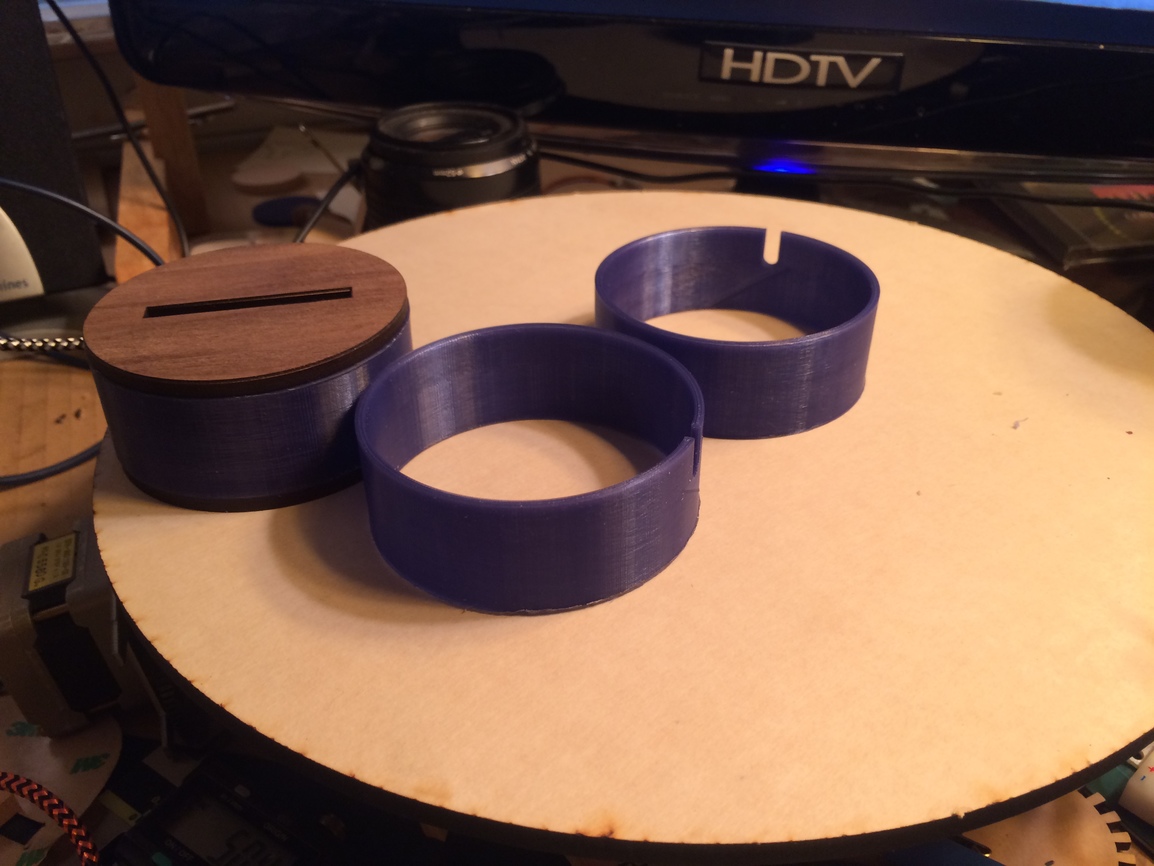

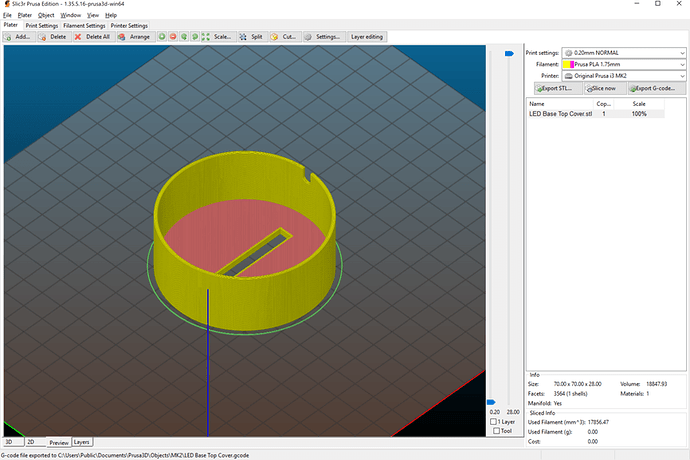

So I made the shell for the LED base on my Prusa MK2.

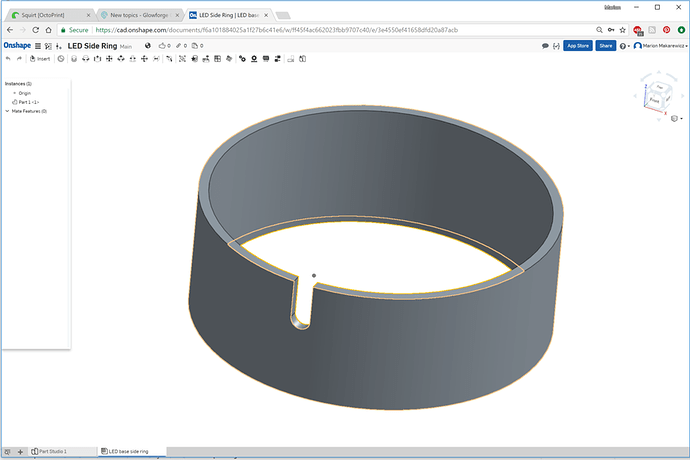

These worked fairly well, although an hour and a half for each section is a bit too much time. So I figured that I could just make the sides with the 3D printer. The ring takes less than an hour to print. Kind of like the light blue that shines through the blue PLA. Not sure if I’ll add some type of inside screen to keep the light from shining out of the side.

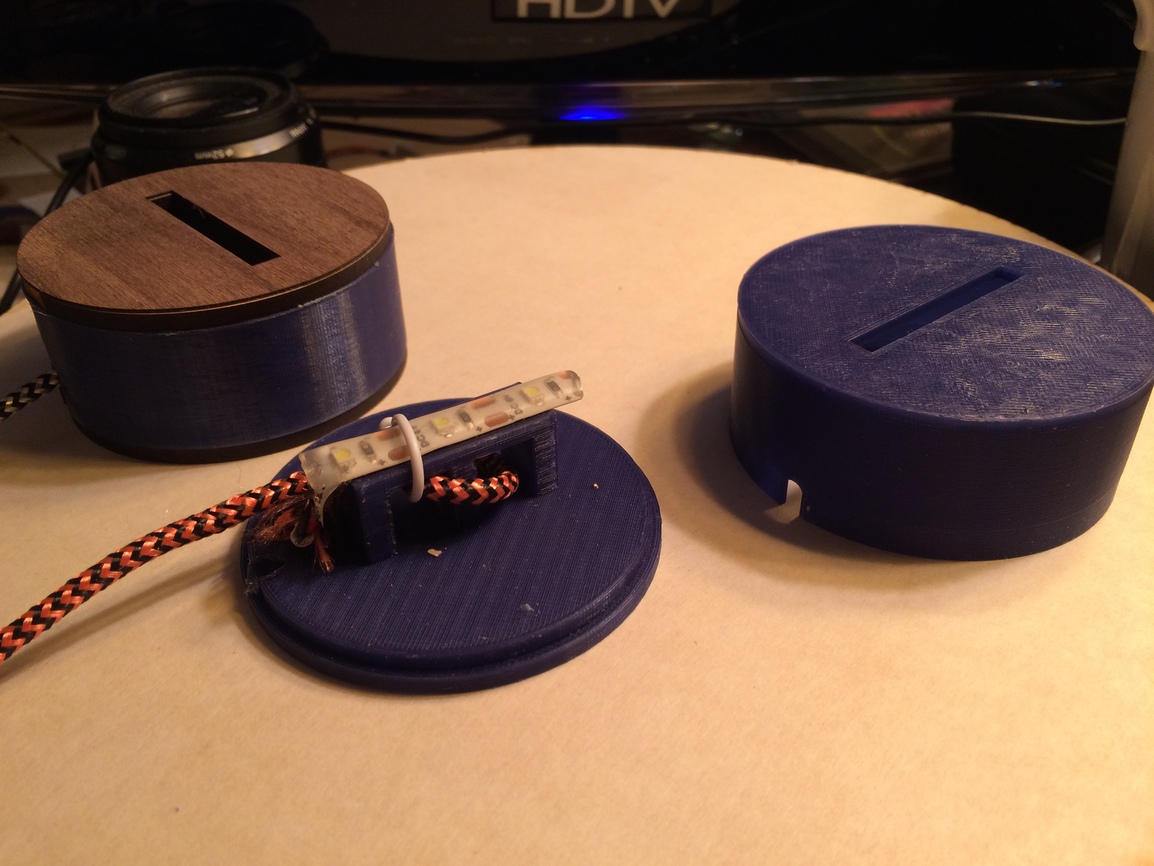

I can keep cranking out the rings and cut the tops and bottoms on the laser to speed things up. I use the medium draftboard with a smaller piece that goes inside the lager piece and that allows for a snap fit to the 3D printed side.

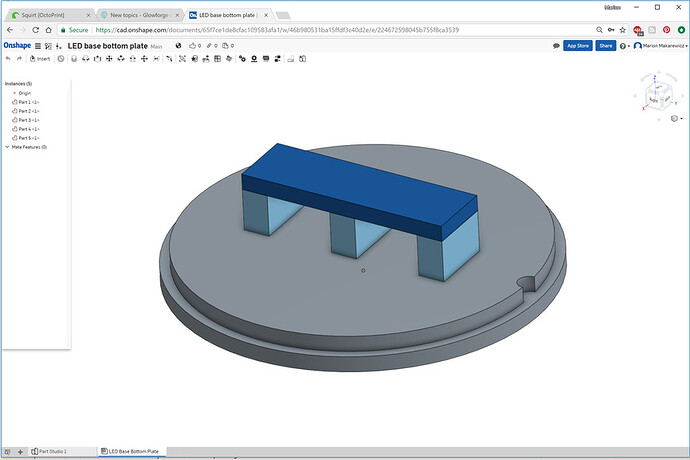

Here are the parts minus the walnut veneer top skin to place to make it look a little more polished.

This is the bottom that snaps into the ring. The LED strips have an adhesive backing that allows it to be afixed to the bench to raise the lights slightly up.

Graphics are from openclipart. I like the jelly fish. One problem is that I used a scrap of acrylic without masking to this sign so you can see the flashback round the perimeter. These are still in the proof testing stage, but seem to work. Need to tweak the layout a bit. Also will post more details as to parts and files.

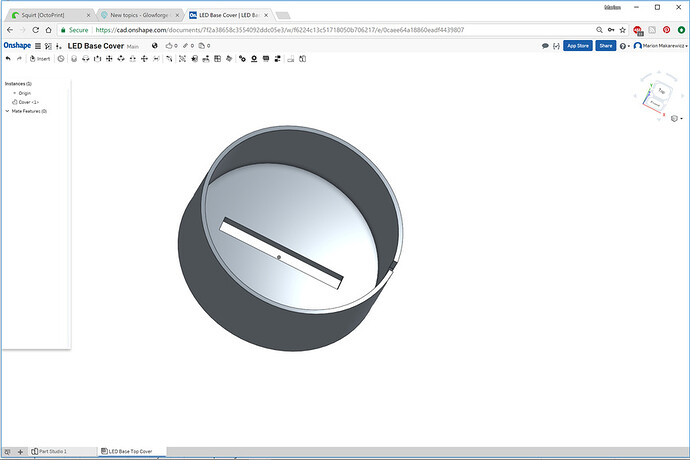

3d files:

Here’s the OnShape Link. You can find the other parts too. All my stuff is available since I have a free account.

Here are three STLs. Top cover and bottom plate go together and make a complete base. The side ring is for when you want to do the top and bottom plates with the Glowforge. The slot thickness for the acrylic is made for Chemcast .205-.21". Glowforge Proofgrade thick acrylic is slightly thicker, I think around 5.75mm.

LEDBaseSTLs.zip (145.0 KB)

Now I should go back and do this all with variables and parameters so you can customize the file easier. Or not.

There are tons of posts about LEDs and edge lit things…some of them mine…but do you perhaps have a link to

There are tons of posts about LEDs and edge lit things…some of them mine…but do you perhaps have a link to