UPDATE: PERSONAL ADVICE TIME… (POSTED LOWER AS WELL)

I wouldn’t fully recommend doing the whole process I did at the top of this thread. That was advice for when I thought just one side was going to break… but I see now that if one side breaks, it’s a very short time window until the other side does too. So, all of this thread was, well, literally a half-measure that wouldn’t stand up over time.

I don’t know the specific technique I’d use, but in retrospect if one side breaks (and you’re fixing it yourself), you should probably disconnect the camera wire bundle, wedge a thin scraper in the gap, and remove the entire lid.

When it’s fully released the entire contact area is obviously fully exposed and can be better worked with. I saw all the dry adhesive, could scrape off a lot of it, I goo-gone’d it and scrubbed off a lot of the residual, so I had a clean surface to work with. That gave me a lot more access to put a clean layer of E6000 down.

________________________ ORIGINAL POST BELOW _________________________________________

OK, I posted in the Problems and Support area about my recently detaching glass lid.

( Glass hinge detaching issue... about 1.5 years later :( )

But since I’m attempting a fix myself (don’t live in an area that would easily allow shipping it back to GF) I figured I’d post a different thread on what I’m doing, and will post the results when I have more info.

SO!!!

After reading a great deal on what adhesives are best for attaching glass to metal, I went with a two part solution.

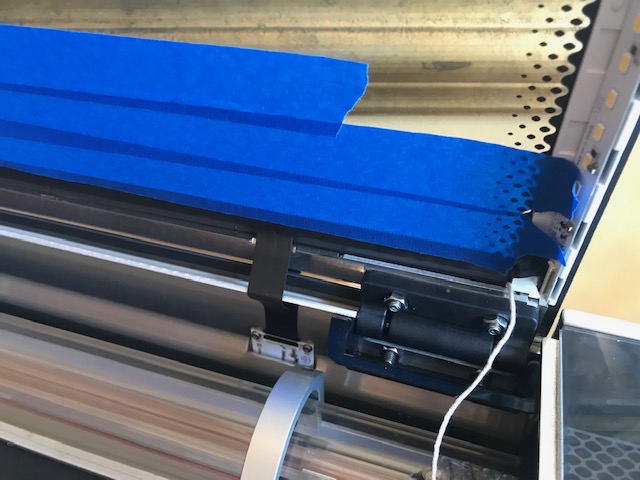

First, I taped off the glass in the area, just in case the adhesive(s) left some nasty residue.

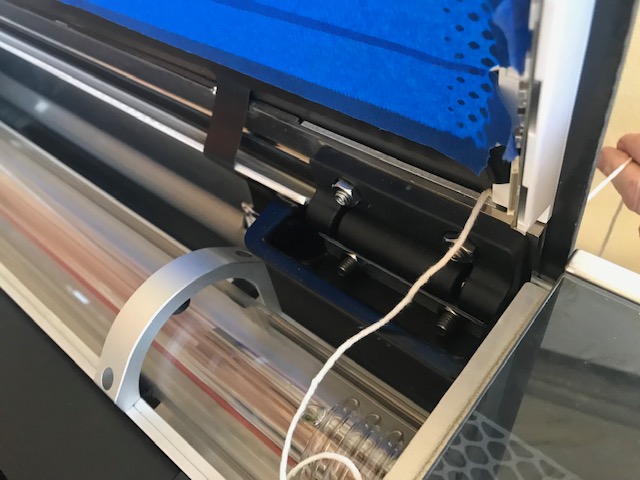

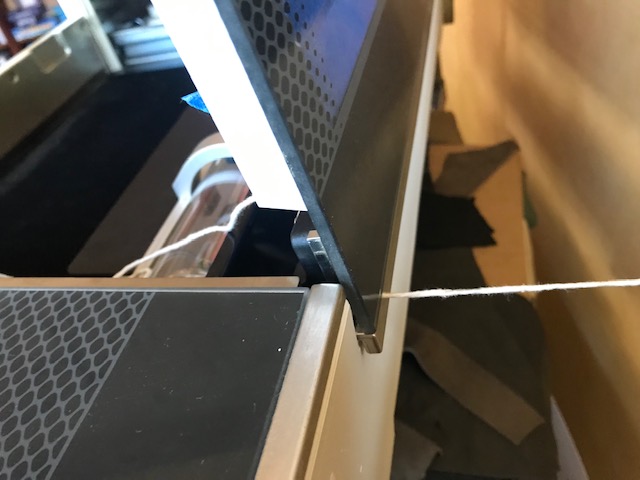

Then I threaded a line of twine through the gap between the glass and metal. I did NOT cut the line off the roll, since I didn’t know how to best use the string anyway. The goal here was to use the line almost like “floss” and allow me to spread the thick adhesive around in the gap.

For this area, I grabbed a tube of E6000 (which loads of sources online claim to be pretty awesome for these two materials) and ran a thick line of it along the top of the gap.

From there, I used the twine “floss” line to pull the bead down into the gap better. I actually repeated this process about 3 times, laying down a line, then spreading it into the gap again.

Yes, it’s still a wee bit messy, even with the masking, but… whatcha gonna do? I cleaned up immediately with some folded paper town edges to try and minimize what I could.

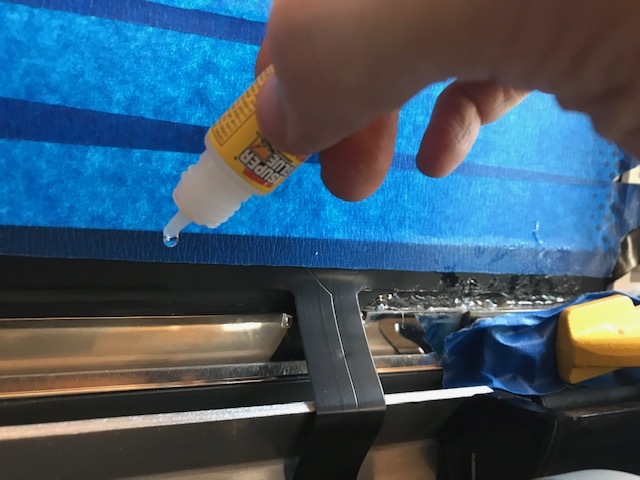

Further in on the lid, the gap was more subtle, not allowing room for the string, but definitely detaching. I used a thin CA glue along this area, which wicks into the opening pretty easily. I wiped up the excess where I could. This would almost certainly discolor the nearby glass if not taped off (I believe).

These two adhesives don’t overlap or anything, they both are in their own “area” of the gap that is split by that area where the lid cables run.

Then I taped a couple bits of wood remnants on the hinge and glass side, and clamped the bittles together reasonably heavily.

Now, I’m going to leave that clamped for at least 2 days, and… fingers crossed… this will work out to be strong enough to not worry about the hinge anymore.

I will probably discontinue using the lid regardless, unless it’s really needed, since often I can just barely lift it up, lower the front side door, and put things in through there.

I’ll post again after that waiting period, and let you all know how it goes.