Hi @sarjanlong, I am so sorry you are having issues cutting through Proofgrade Material! Thank you for taking the time to do some initial troubleshooting. Can I have you check a few more things as well?

Please send photos of all your cleaned optical components, with special attention to any damage you might find:

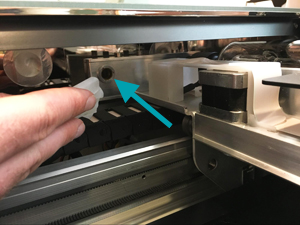

- Both windows

- The printer head window, on the left hand side of the printer head

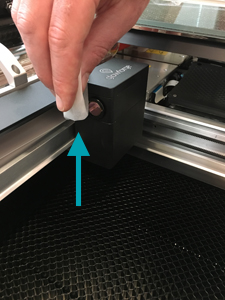

- The laser window on the inside left of the Glowforge

- The printer head window, on the left hand side of the printer head

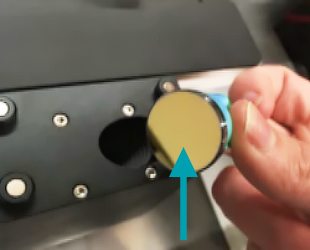

- The printer head lens

- Both sides of the lens, top and bottom

- Both sides of the lens, top and bottom

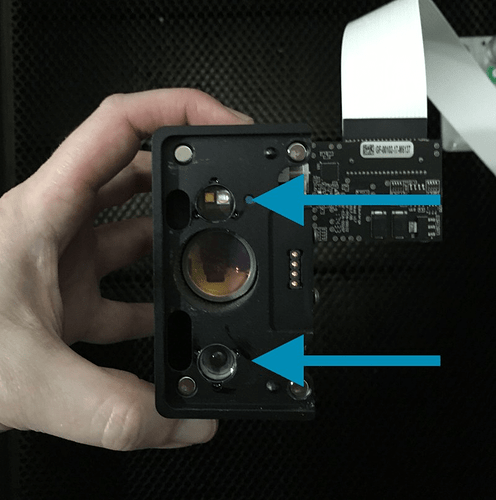

- The 45 degree mirror inside the printer head

- The bottom of the printer head

Once we have those pictures, we’ll follow up with next steps.

Thanks!