Hi! I’m box.

Read on for details.

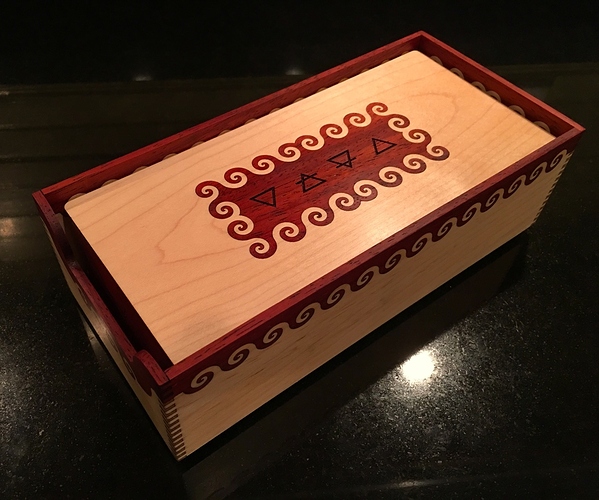

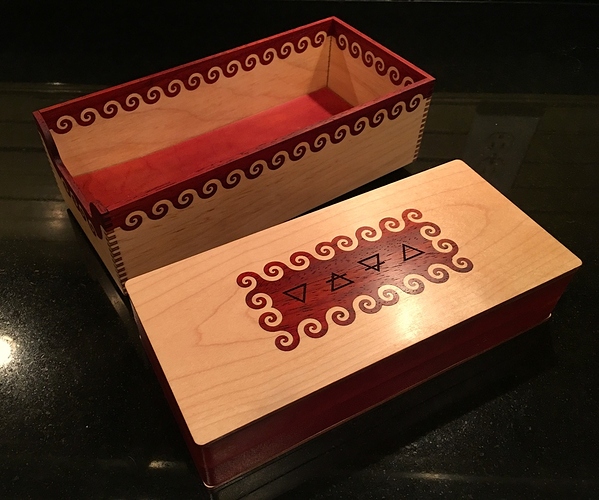

I wanted to make a hero vault that would fit inside my dice tray (scroll down in that post for the dice tray pics) and match it thematically. This is where I ended up.

Notes:

- I’m going to assume you, dear reader, are fairly advanced and don’t need a ton of basic details.

- The overall box dimensions are 8 x 3-9/16 x 1-13/16" ( 203 x 90 x 46 mm)

- All woods in this project were 1/8"

- All visible surfaces were sanded to 1500 grit

- The woods were finished with clear danish oil

- The leather was dyed with tan Eco-flow waterstain

- The leather was finished with Tandy hide rejuvenation creme

- The engraving is a representation of the classical physical elements

- No proofgrade was harmed in the making of this box, so please don’t ask for settings.

Onto the fun stuff!

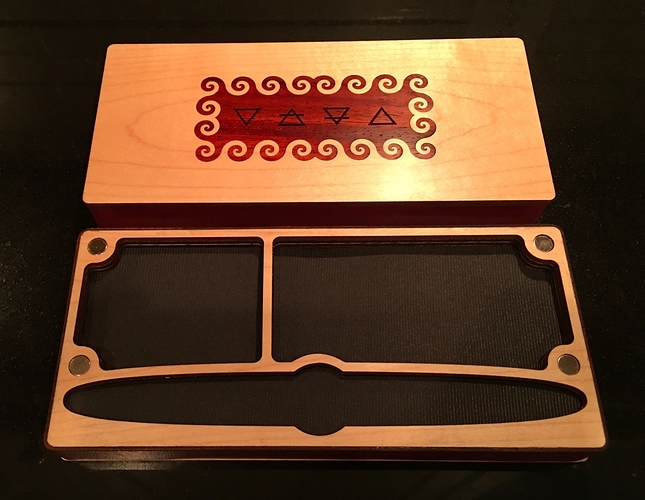

The lid is inlaid and engraved, and finished with danish oil. The top was assembled first, the inlay is full cutouts, not veneer in pockets.

Maple, Padauk

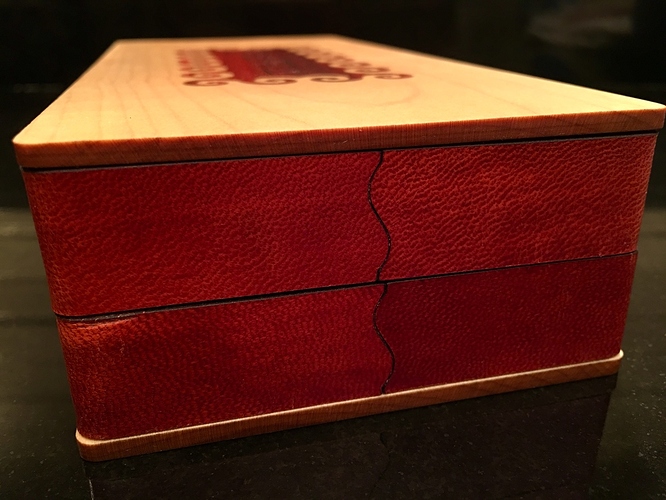

Now you see the sides, they are wrapped in veg-tan sheepskin (From Tandy, I don’t know the weight, it comes in at 0.07" thick). I find that the waterstain tends to curl and shrink the leather, as well as toughen it up. So, I first stained it and let it thoroughly dry while it was clamped curled into a cylinder shape. The cylinder curve prevented the bulk of the natural curling you would get otherwise. Sadly I didn’t take any pictures of that process, but if you ever do this you’ll find out what I mean really quickly.

Maple, Padauk, Sheepskin

Detailed view of the sides. The leather is glued into place using contact cement, which has a little play to get it just right for the first couple of minutes. Once it sets, though… if you want to adjust the position it’ll rip your leather in half before it gives up. Guess how I know that? Let’s just say I’m glad I cut a couple of spare leather strips.

Maple, Padauk, Sheepskin

The problem with boxes of this size is that the circumference grows very quickly. Unfortunately, it’s too large to do a single strip of leather around the box (about 22.5" (570mm), well over 19.5" – can’t even fit on the diagonal), so I had to do two strips and join them as cleanly as I could. Each of the short sides has a seam that is subtly decorative. I wanted it to be simple but intentional; this is where I ended up.

Maple, Padauk, Sheepskin

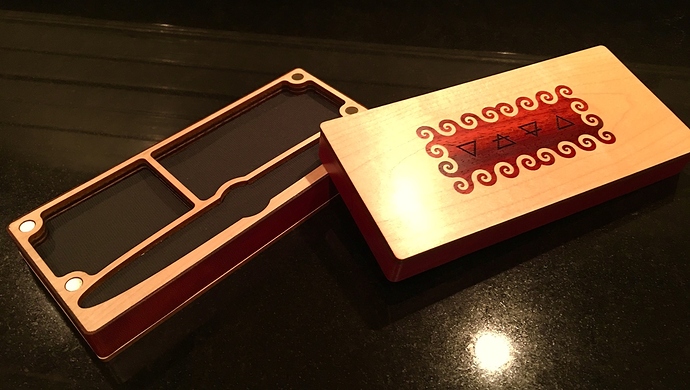

The inside of the box is designed to be a “hero vault” for D&D. Yes, I’m a big geek, but you knew that already. This style of box, of course, could be made into anything. If you look closely, you can see how I constructed the box with layers. The middle layers are Baltic birch plywood, all visible surface layers are maple. The box is made with symmetrical lid and base, each constructed of a total of 7 layers. 5 layers of BB ply sandwiched between maple layers.

Maple, Padauk, Sheepskin, Headliner fabric, Baltic birch plywood, Neodymium magnets

A head-on view of the layout. You can’t see how it’s fully constructed by there are registration holes that accepted a dowel directly under the magnets and 2 more in the lower corners, making a total of six registration dowels. This kept the BB layers properly aligned for gluing. Six dowels may have been overkill but other boxes I’ve made with two felt like it wasn’t enough. And yes, I cut my dowels to length using the glowforge, of course. Saws are for suckers.

Maple, Padauk, Sheepskin, Headliner fabric, Baltic birch plywood, Neodymium magnets

Now a few views of it filled up with intended items. The headliner is glued in with rubber cement, and all is double layered. That works out to about 0.3" (8mm), which is enough thickness to gently “trap” the pencil and the miniature.

Maple, Padauk, Sheepskin, Headliner fabric, Baltic birch plywood, Neodymium magnets, Marco miniature, 2 sets of chessex dice, Hand-turned black-and-white ebony mechanical pencil

While you can’t see why, you might notice that the foam in the pen compartment sits a bit higher than the others. That’s because one of the BB layers (the second from bottom) is cut without the pen cavity. This makes a false bottom which raises the pen up enough (2 layers of BB) so that it’ll be properly cushioned and easy to remove.

Maple, Padauk, Sheepskin, Headliner fabric, Baltic birch plywood, Neodymium magnets, Marco miniature, 2 sets of chessex dice, Hand-turned black-and-white ebony mechanical pencil

Maybe red/purple swirl dice would complement the padauk? Yes, I have a lot of dice. Yes, I know, shush.

Maple, Padauk, Sheepskin, Headliner fabric, Baltic birch plywood, Neodymium magnets, Marco miniature, 2 other sets of chessex dice, Hand-turned black-and-white ebony mechanical pencil

Final thoughts:

It’s a labor-intensive construction method, but the results are pretty impressive in person. If I were going to do it again, I would probably oil the visible wood surfaces and the leather before gluing them to the box. As it stands, I dyed and dried the leather, sanded the visible surfaces, then glued everything together, and oiled everything last. The side effect of this was that I had to be careful not to get danish oil on the leather and not to get leather creme on the wood.

My main reasoning was that I didn’t know if the creme would change the size of the leather… would it swell up? If it did my fit was completely blown. I don’t know, this is one of those cases where a shortcut might be a bad idea. I’m sure someone out there has done something like this and is saying “Dave, you dummy” right now, but hey, it all worked out

Go forth and make stuff!