Disclaimer: If you are unsure of either of the following:

- “why would you want to do this?”

- “what problems could this cause?”

… then turn around and walk away, this isn’t for you ![]() (I am only half kidding!)

(I am only half kidding!)

The bottom line is that this may elevate your fire risk, reduce your air assist fan life, or cause a change to the fumes generated by your cuts. It may not do these things too, there’s just not enough data to say for sure either way. I’ve been using them for some time without any apparent ill effects, but that’s just one person with one machine.

This is on the very edge of “beyond the manual” and should not be tried without abundant caution.

Now that that’s out of the way: I’m clearing out my list of ancient projects I’d been meaning to try. Here’s one:

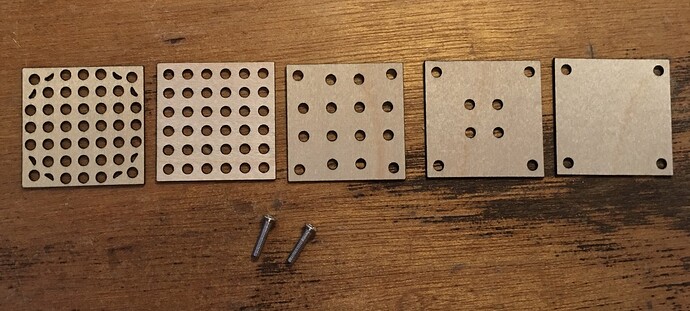

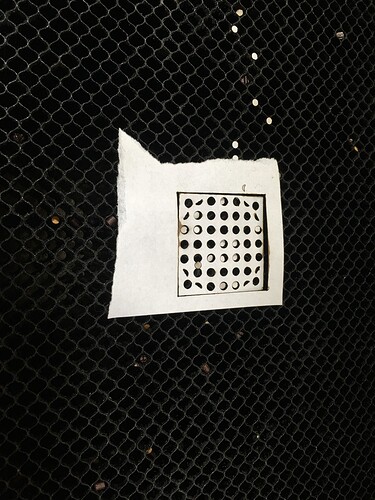

This may be all that an enterprising Glowforger needs to get the idea. These are plates that you affix to the intake of the air assist fan to reduce the airflow. Left to right, they range from “slightly reduced” to “no airflow at all”. I feel the need to reiterate: the air assist fan is very important for lots of reasons, not the least of which is to prevent fires… so, basically don’t do this!

But, I know you pack of maniacs… so in the name of science, I tried them all out, and it works very well.

To attach the fan reducer, you take a small screw and insert it in a corner hole, and slip it into the fan case. (when you look closely at your fan it’s obvious how it works) The caveat is that you need a rigid thin material, I used 1/32" plywood, it’s possible that a nice heavy cardstock would work too. 1/8" material will not fit, the clearance behind the assist fan is very tight.

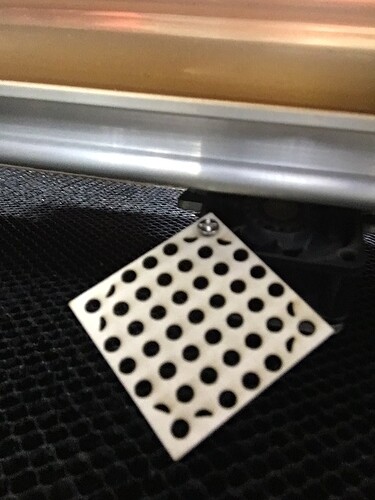

Detail, terrible photo quality, but here you go. The red arrow points to one of the corner holes in question:

Now, rotate your fan reducer into position and place the other screw.

I just slipped the screws into place, they don’t need to actually screw in, they just need to fit the holes. The suction from the assist fan will keep everything firmly in place.

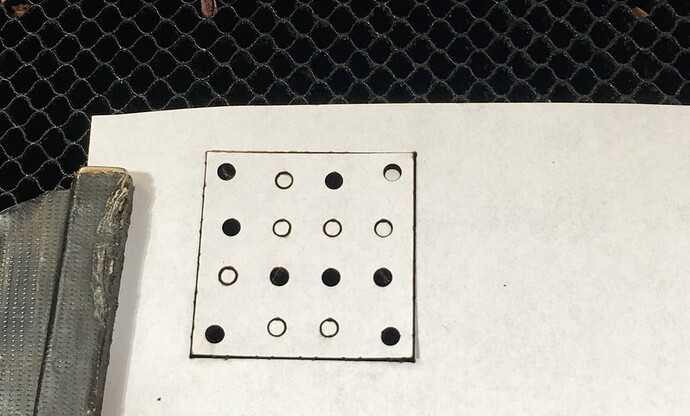

Here are the results, I cut these shapes out of standard printer paper with no mats or anything.

Some of the small holes fell through the tray, none blew away. This cut was made with the middle reducer above:

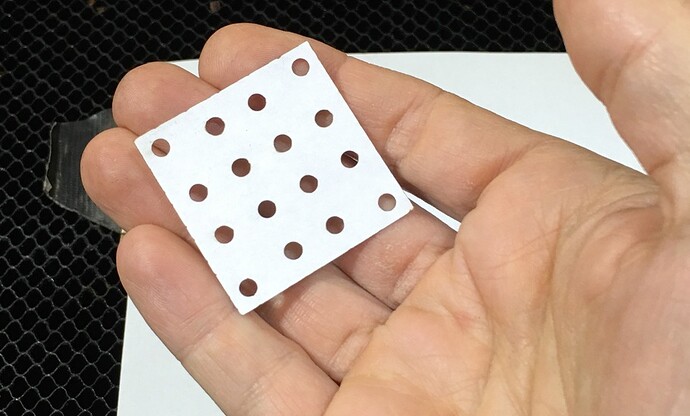

Hand for scale:

I then went and tried the rightmost reducer. This solid plate should prevent all air assist airflow. I made no attempt to hold my small scrap of paper in place, this was the result:

The paper stayed put but the heat did bow it up some, which was not the best result. It’s probably a good idea to hold the paper down regardless, keep it flat. The point is that it didn’t blow away.

So. If you want to try this, here’s the file. But, one last time, click here to confirm that you understand what you’re doing:

I am crazy enough to try this and understand there may be risks, yet here we are, and I'm clicking anyway:

… ahh, I knew at least someone would want to try this. ![]()

Be sure that your reference square is 1" per side if you want to modify this.