There’s a great tutorial here on cutting without the crumb tray when you want to work with thicker material. If you want to know the numbers and theory behind it, go read that first, and then come back. Thank you, @henryhbk!

This method uses the digital calipers you should already have, and the not-used-often-enough ZERO button. We’re going to go through the steps from the tutorial above, but without any math or writing down numbers.

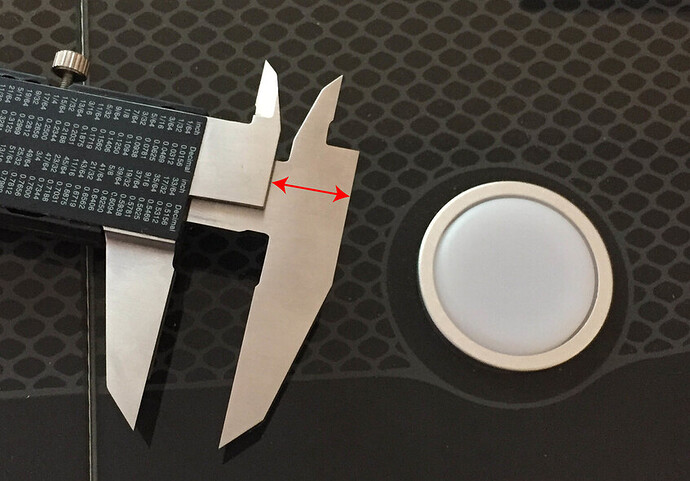

The first step is to find the height of your crumb tray’s surface above the bottom of the Glowforge. The honeycomb actually sits slightly below the top of the tray. Measure that distance with the step measurement part of your calipers:

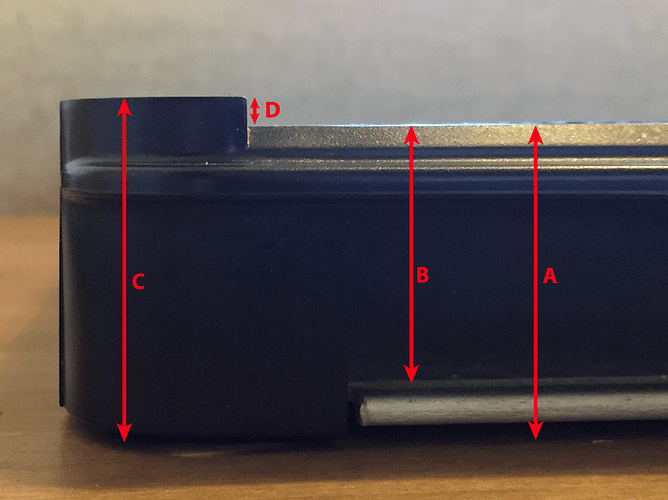

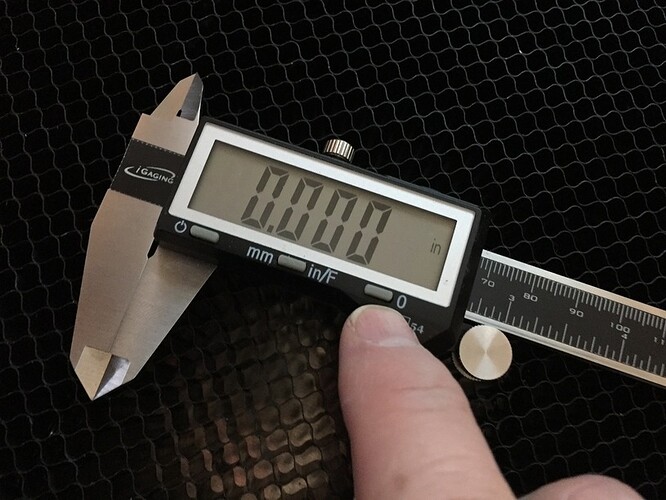

In case you didn’t know, the step measurement is the part indicated by the arrows here:

Now zero the calipers there:

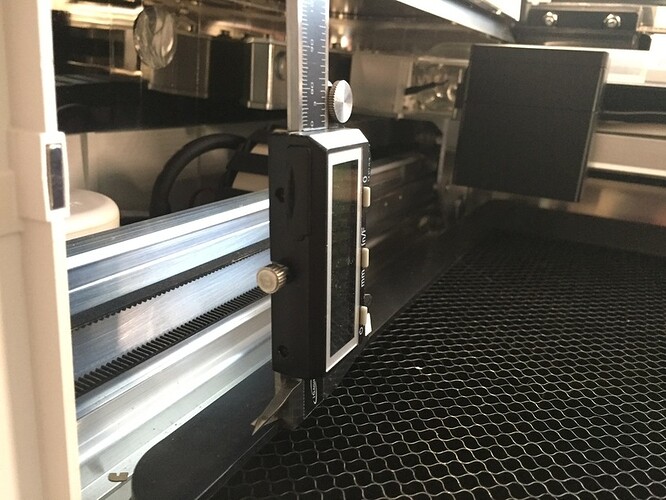

With the depth measurement of your calipers, measure the distance from the floor of the Glowforge to the top of the tray. There’s just barely room to squeeze it in there:

Since we already zeroed with the offset of the honeycomb from the top, you’ll need no math. The number you see on the screen is the height of the honeycomb above the floor. Commit it to memory, since it’ll be your new most-important number, and you’ll use it again and again. Or write it down, I suppose, but since I promised no writing I’m not going to tell you to.

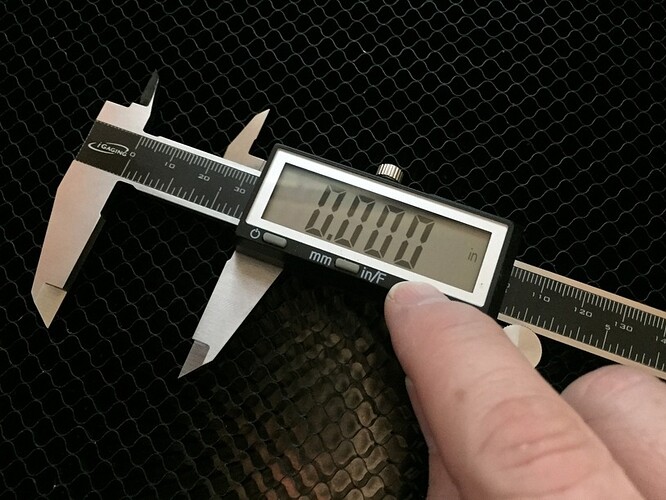

Now close your caliper’s jaws and zero again:

Open the calipers to the number from before. Zero again. This is now your baseline for no-crumbtray measurements. In the future you can skip right to this step—just open your calipers to this number and hit zero.

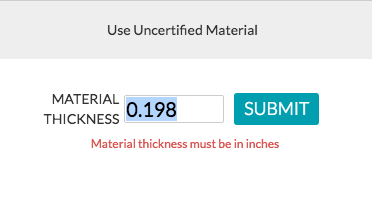

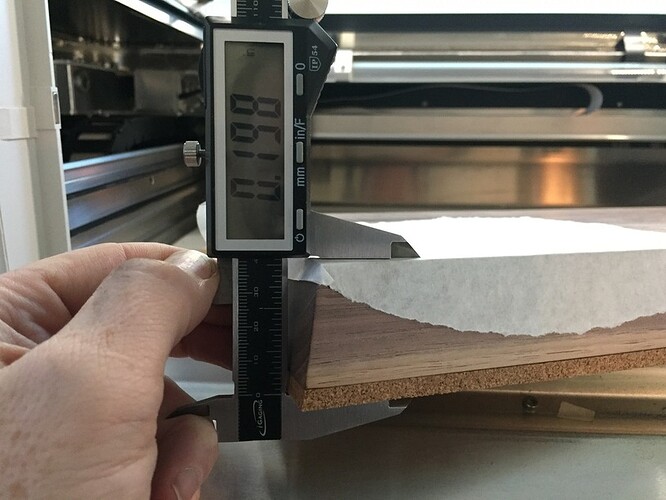

Measure your material. I’m engraving a piece of 6/4 walnut that I’ve made into a serving board. I put a piece of cork underneath to raise it up. When I measure the entire thickness, it tells me it’s .198" (because we re-zeroed it at the height of the crumb tray). If your measurement is negative, you’ll need to raise your piece. If it’s thicker than .4 (subject to change, I understand), you’ll need to lower your work.

Enter that into the material thickness interface and you’re ready to go!

)

)